Bioreactors are ideal tools for harnessing the power of nature’s processes. By creating a controlled, confined environment for fermentation and cell growth, these systems enable the use of organisms and cellular components to produce essential commodities for various applications.

Introduction

The technology and applications of bioreactors are diverse, spanning various industrial sectors and even urban spaces. As such, bioreactors play a crucial role in shaping a more sustainable future, aligning with the principles of Solarpunk. Notably, their process efficiency, low resource intensity, and cost-effectiveness make production more versatile and accessible. This aligns with the vision of Industry 5.0, where stakeholders actively contribute to economic and industrial processes.[1]

Looking back through history, fermentation processes have been used for millennia to produce food and beverages (fermentation is the conversion of sugars into alcohol, gases, or acids by microorganisms). In the past century, biogas (methane) and biofuel (diesel, methanol, ethanol, etc.) production from agricultural waste and wastewater have proven to be cost-effective, safe, and efficient.

Bioreactor technology is based on the principle of inoculating a liquid or solid input, such as a growth medium or biological material (in the case of fermentation), within an artificial vessel—typically made of metal or other inert materials—to cultivate or utilize cells and cellular components.[2][3] This controlled environment optimizes conditions to maximize yield from the desired bioprocesses and reactions. Key factors in bioreactor processes include selecting the appropriate growth medium (e.g., essential chemicals for cell growth and nutrient-rich materials) or biological material (e.g., agricultural waste) to achieve the desired output. Bioreactor designs vary based on process requirements, including flow dynamics, batch size, and aerobic or anaerobic conditions. Their adaptability in size and volume makes them highly scalable for different demands. In urban settings, bioreactors offer flexibility and can be installed even in limited spaces.

Furthermore, inoculation involves introducing cells from various sources—such as plants (e.g., algae), fungi, mammals (e.g., animal cells or human stem cells), yeast, bacteria, or cellular components (e.g., enzymes)—into the bioreactor. This enables the production of base commodities and other biological materials. By confining active organisms and cellular components within a controlled environment, bioreactors reduce the risk of contamination, particularly in processes involving genetically modified organisms (GMOs), compared to open-field methods.[4][5]

Use Cases

Bioreactors can be adapted to produce a wide range of valuable chemicals, gases, and food components. Additionally, they can be used for extracting and purifying chemicals from environmental sources or specific feedstocks. Below is a brief overview of the main applications of bioreactors:

Gas Generation (e.g., Methane, Hydrogen)

Bioreactors facilitate anaerobic digestion, where consortia of microorganisms decompose organic substrates in oxygen-deprived environments, producing biogas primarily composed of methane (CH₄) and carbon dioxide (CO₂). This biogas can be upgraded to biomethane by removing CO₂ and impurities, making it suitable for energy applications.[6]

The raw materials used for producing biogas are sewage, manure, green waste, wastewater, municipal waste and food waste.

Additionally, bioreactors are employed in biohydrogen production through dark fermentation processes, where fermentative bacteria metabolize carbohydrates to yield hydrogen gas (H₂). This valuable gas can be further utilized for industrial processes and fuel cell mobility.[7]

Gas Capturing (e.g. CO₂ Sequestration)

For gas capturing, biofilters and biotrickling filters utilize microbial communities to oxidize volatile organic compounds (VOCs) and other pollutants, thereby purifying air streams. In CO₂ sequestration, microalgal bioreactors capture CO₂ through photosynthesis, converting it into biomass that can be further processed into biofuels or other valuable products. These technologies not only provide renewable energy sources but also contribute to environmental remediation, aligning with solarpunk ideals of sustainable living and ecological harmony. By decentralizing energy production and waste management, communities can achieve greater self-sufficiency and resilience, reducing reliance on fossil fuels and mitigating greenhouse gas emissions.

Largest Biogas Plant in the World

The world’s largest biogas plant is located in Korskro, Denmark. This impressive facility, operated by Nature Energy, can process 1 million tons of food waste and agricultural residues annually. It produces up to 27 million cubic meters of biogas each year, which is fed into the European natural gas grid.

To put those numbers into perspective: with 27 million cubic meters of biogas, roughly 7.7 million cars could drive once around the world! (based on 11.48 kilometers per liter or 27 miles per gallon for a mid-size biogas car)

On top, it is the only large-scale biogas plant with CO2-capture technology onsite, making it a significant contributor to sustainability and the circular economy.

Fuel Generation (e.g., Biodiesel, Ethanol, Methanol):

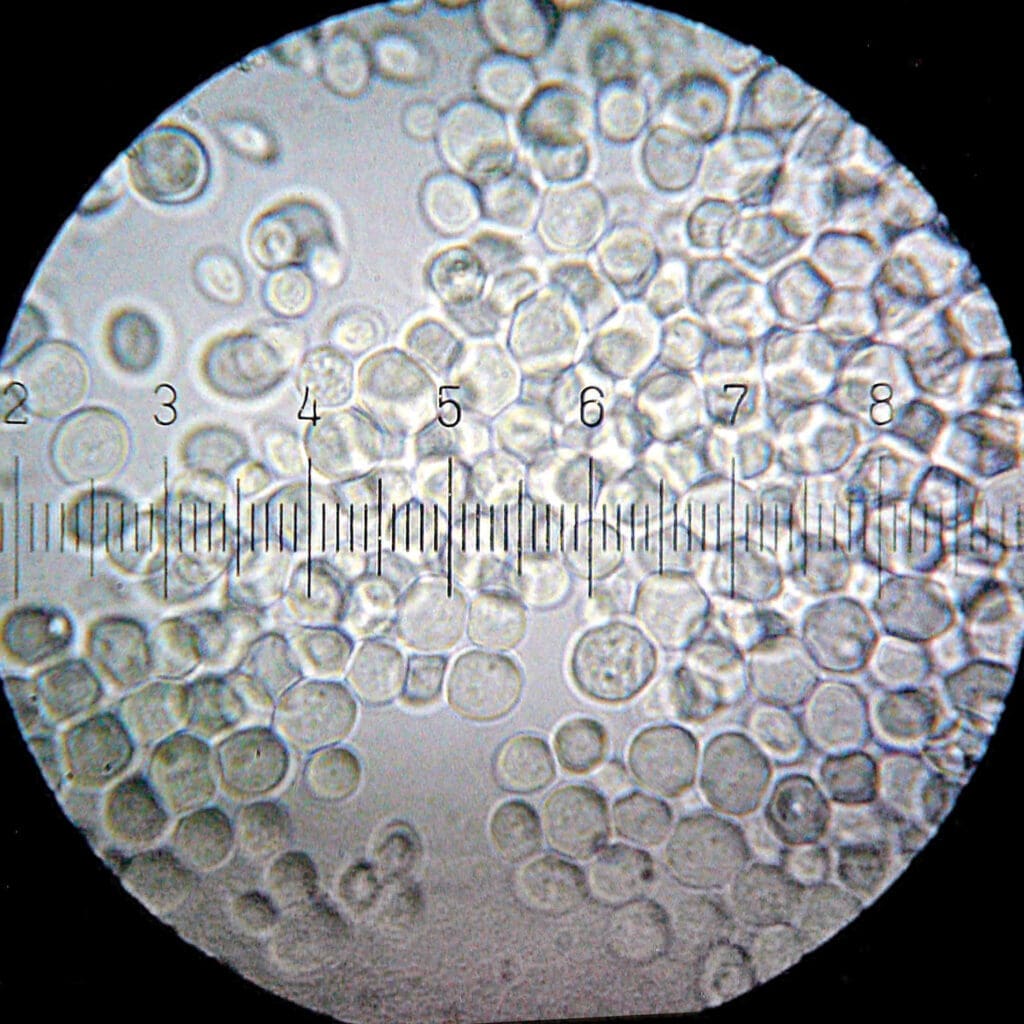

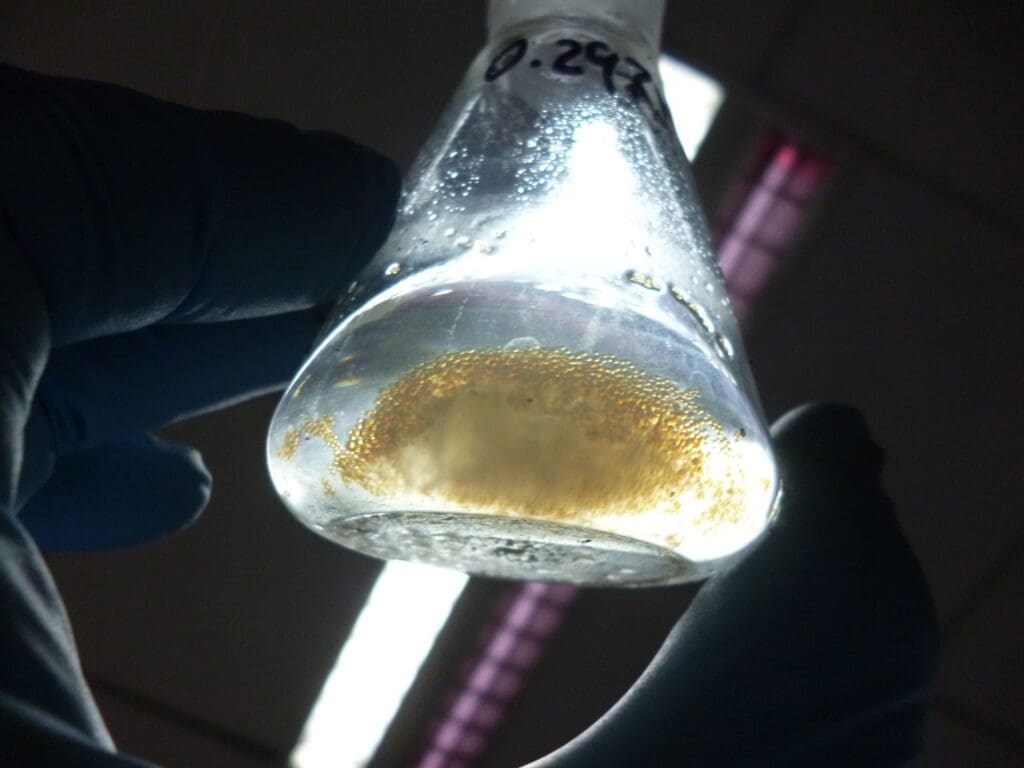

Bioreactors are integral to biofuel production processes. In ethanol production, bioreactors provide controlled environments for the fermentation of sugars by yeast strains like Saccharomyces cerevisiae, converting glucose into ethanol and CO₂ – similar to beer brewing.

Methanol can be produced via bioconversion processes involving methanotrophic bacteria that oxidize methane under aerobic conditions. Innovative approaches integrate renewable energy sources by utilizing excess wind power to operate photobioreactors that cultivate microalgae.[8] These algae are harvested and processed to extract lipids, which are further processed to produce biodiesel, demonstrating a synergistic approach to sustainable fuel production.[2]

This integration of biological processes with renewable energy sources exemplifies Solarpunk principles by promoting decentralized, eco-friendly fuel production methods. Such systems can reduce dependence on centralized fossil fuel infrastructures, empower local communities, and stimulate green economies.

Further Use Cases:

Active Biomolecules, for example enzymes, play also a very important role. Enzyme Membrane Bioreactors (EMBRs) facilitate continuous enzyme synthesis and purification, enhancing industrial applications while reducing reliance on chemical catalysts. For environmental purification, bioreactors have been very successful in wastewater treatment, air filtration, and soil bioremediation, leveraging microbial metabolism to degrade pollutants. In material production, they enable the microbial synthesis of biopolymers, offering biodegradable alternatives to conventional plastics.

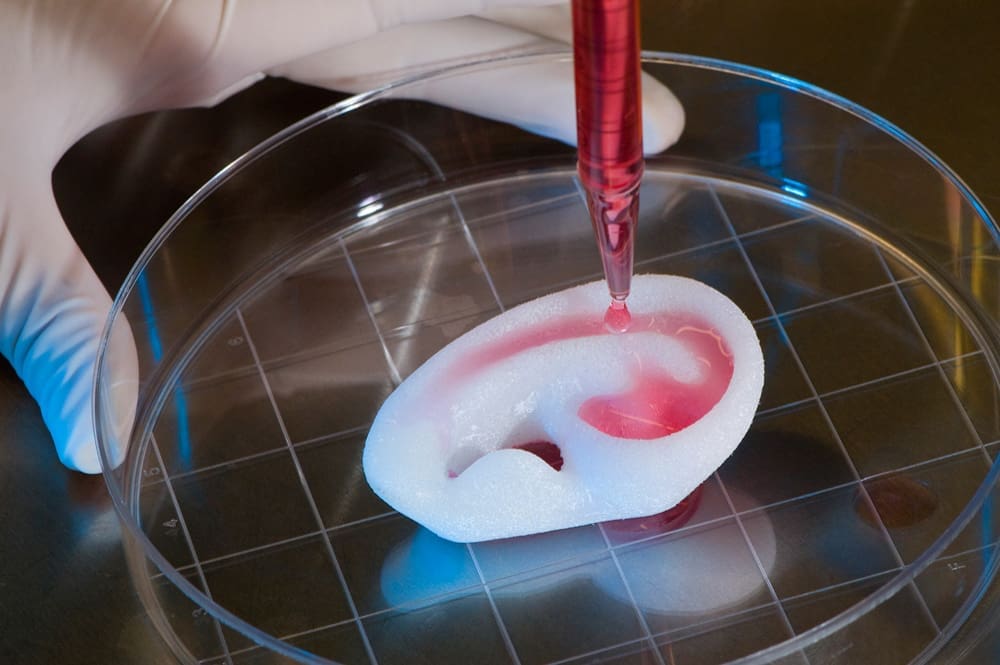

The medical field benefits from bioreactors in tissue engineering and pharmaceutical production, optimizing conditions for cell growth and vaccine manufacturing. In cosmetics, plant cell culture bioreactors generate bioactive compounds sustainably, reducing the need for large-scale agriculture.

Given the vast number of different use cases and applications, we will provide follow-up articles for further elaboration.

Future of Bioreactors:

A quantitative analysis of market forecasts for bioreactors shows a growing demand for this technology, demonstrating its increasing relevance in global operations. Over the past two decades, the market has grown at an annual rate of 12-14%. It is forecast to increase from $16.7 billion (as of 2024) to $51.7 billion by 2035.[8]

As the biomedical and alternative food sectors continue to expand, the range of bioreactor applications is expected to grow steadily, driven by the need for innovative solutions. The trend for tailored reactor designs, single-use variants, and variable batch sizes sparks innovation, which itself created market inertia that will lead to wider application of the technology in the future.

With climate change, resource scarcity, supply chain disruptions in energy and food, extreme weather events,[9][10] emerging diseases,[11] and environmental cleanup efforts, bioreactors can become essential components of future urban spaces.[12] They enable the local production of essential commodities quickly and safely within neighborhoods. Their sterile, controlled environments make bioreactor-based production less vulnerable to external disruptions, which are expected to increasingly impact conventional industrial and agricultural systems.

Medical progress will increasingly depend on tissue engineering, vaccines, high-tech antibiotics, and other biologically active compounds—most of which will likely be produced in bioreactors.[13] While bioreactors are widely used in centralized production and urban settings, their versatility makes them equally valuable in rural areas. An example beyond a developed economic setting are frugal innovators that have simplified bioreactor designs to basic components, making them accessible for waste-to-gas production in households and communities.[14] This provides a cheap, safe, and sustainable energy source for cooking and other applications, replacing hazardous fuels like coal and reducing environmental and health risks.

Overall, bottom-up approaches will most likely have great impact on shaping the image of Bioreactor usages, with small scale, cheap, but innovative bioprocesses taking the lead outside developed economies. Even within developed economical settings, so called “miniature” Bioreactors will grow in popularity because their industrial and urban applicability is highly versatile.

Bioreactors in Solarpunk Communities

We hope this discussion has highlighted the significance of bioreactors, their vast range of applications, and the technological sophistication behind them. By harnessing the power of evolution and utilizing biological processes, bioreactors will play a crucial role in producing essential commodities, food, and medical products in the future. Whether in urban or rural settings, developed or developing economies, high-tech or low-tech industries and solutions, the fundamental principles of bioreactors and their processes are indispensable for a more sustainable and resilient future. Bioreactors are not only a key technology today but also have a vital place in shaping a Solarpunk world driven by sustainability, innovation, as well as ecological and social balance.

Sources:

[1] https://research-and-innovation.ec.europa.eu/research-area/industrial-research-and-innovation/industry-50_en

[2] https://atlas-scientific.com/blog/bioreactor-applications

[3] https://pharsol.com/knowledge-hub/blog/what-are-bioreactors-used-for

[4] https://www.sciencedirect.com/topics/immunology-and-microbiology/bioreactor

[5] https://bioreactors.net/about/what-is-a-bioreactor

[6] https://www.sciencedirect.com/science/article/abs/pii/S073497502100015X

[7] https://www.sciencedirect.com/science/article/pii/S187661021201466X

[8] https://www.power-technology.com/features/flora-to-fuel-could-wind-powered-algae-make-bioreactors-competitive

[9] https://impact.economist.com/projects/trade-in-transition/climate_change

[10] https://climatechange.chicago.gov/climate-impacts/climate-impacts-agriculture-and-food-supply

[11] https://health.ucdavis.edu/news/headlines/experts-warn-climate-change-will-fuel-spread-of-infectious-diseases-/2024/03

[12] https://architizer.com/projects/urban-bio-reactor

[13] https://www.mpg.de/8990858/influenza-vaccine

[14] https://link.springer.com/referenceworkentry/10.1007/978-3-030-22759-3_177-1